Brandname: MTM

We are one of leading manufacturers of super-fine ground calcium carbonate powder in Vietnam

Quality Control

Quality control systerms ISO9001-2000 and English imported equipment.

Production line

Synchronous-modern production-line HOSOKAWA ALPINE ( imported from GERMANY) with productivity 70.000 ton/ years

Natural raw material

Natural white limestone located in Quy Hop that valued as one of best mines on over the world.

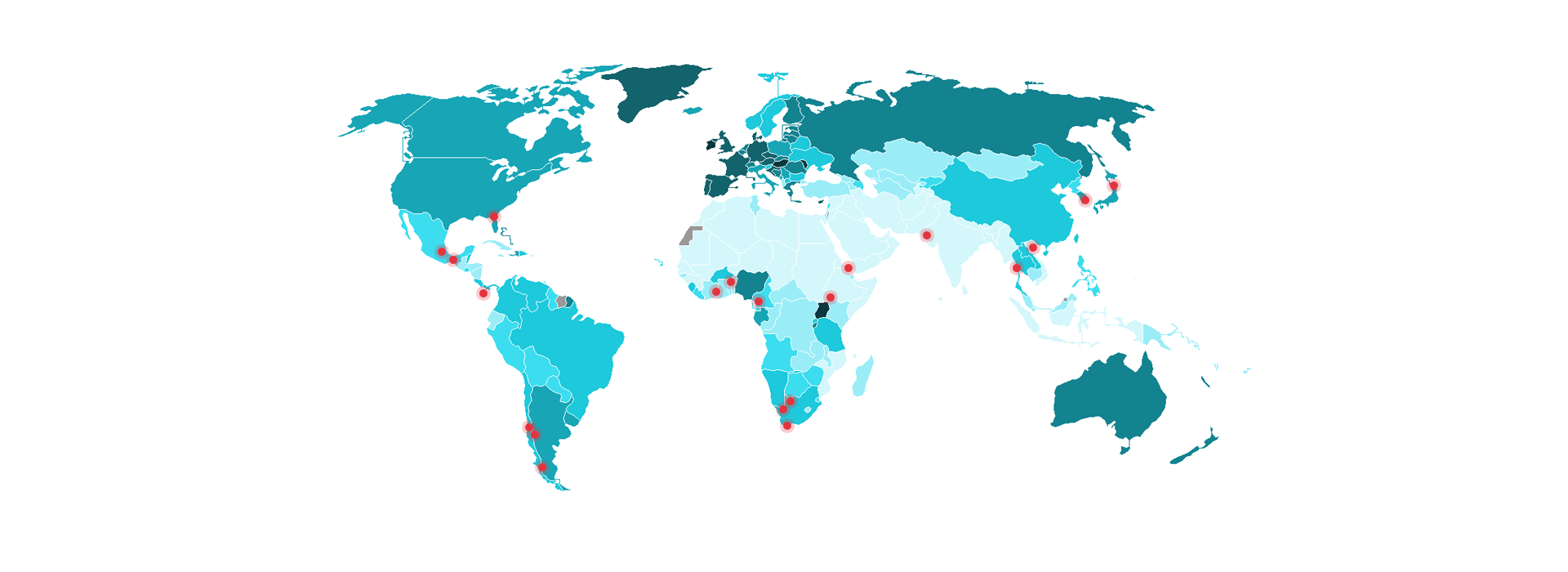

Partners - Clients MTM